NIKKOR Z Lenses: The Art of Pursuing Precision.

Every element, precisely crafted.

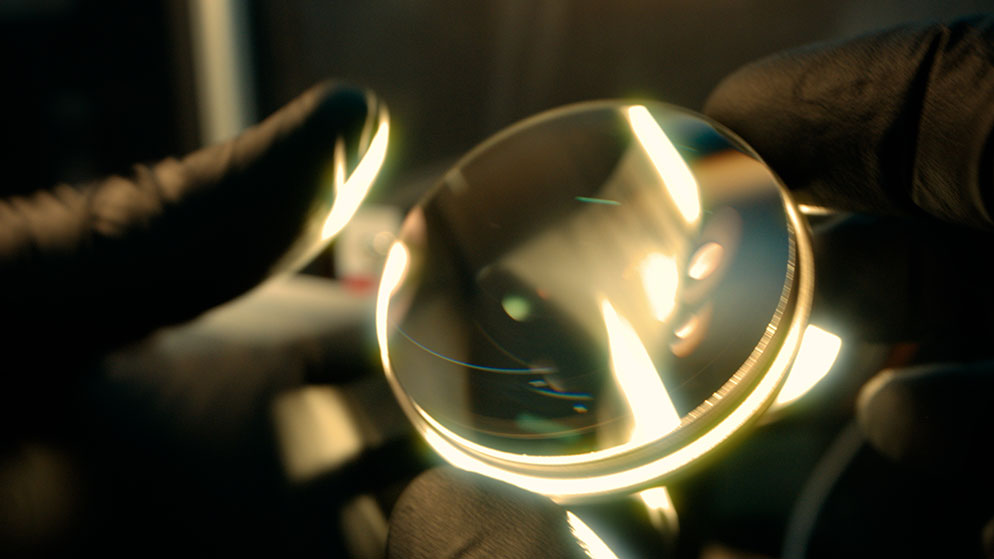

Of these three steps, the most critical is polishing, requiring extraordinary precision to shape the thickness and curvature of the glass according to the exact requirements of the optical design. In fact, our goal is a surface variation of just 10 nanometers—to put this in perspective, that’s approximately 3000 times smaller than the diameter of a human skin cell. For aspherical lenses, which are particularly challenging to manufacture, we use digital technology to enhance the precision of the molds, before each element is meticulously processed on its way to becoming part of a finished lens.

Striving for higher precision.

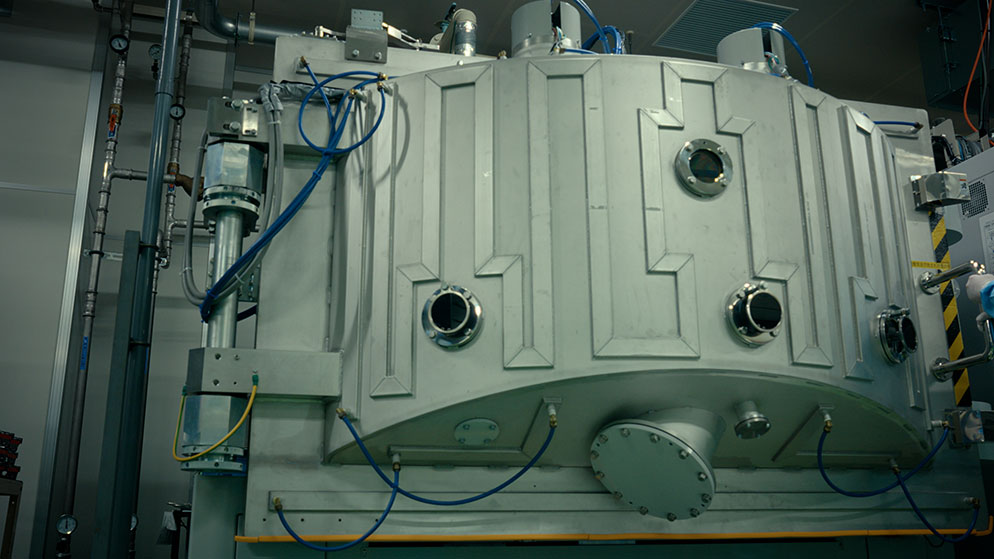

The coatings on NIKKOR Z lenses are absolutely essential for minimizing flare and ghosting caused by strong light sources, and even the tiniest impurities can reduce their effectiveness.

In addition to powerful filtration systems to pull dust and dirt from the air, Nikon’s engineers also mix the coating solutions and apply them with meticulous care.

High-precision NIKKOR Z lenses

NIKKOR Z 600mm f/4 TC VR

A large-diameter super-telephoto lens featuring Meso Amorphous Coat for exceptional anti-reflection performance.

Super-telephoto lenses like the NIKKOR Z 600mm f/4 TC VR are often used in challenging environments such as wildlife and motorsports, where ghosting and flare is more likely to occur. Even under such conditions, this lens captures subjects with striking clarity, thanks to Meso Amorphous Coat. This high-precision coating is made up of a precisely applied base layer, and tiny air pockets formed by the irregular connection of extremely small particles.

To ensure the maximum level of performance, Nikon’s optical designers tested the lens themselves in representative real-world settings. They found that when photographing animals up close, the surrounding scenery was vividly reflected in the animals' eyes, demonstrating the lens’s remarkable rendering power.

NIKKOR Z 24-200mm f/4-6.3 VR

A compact and lightweight travel lens made possible by reengineering the mold for higher precision.

NIKKOR Z's pursuit of precision is not limited to the care we take when shaping and coating lens elements, but also to the molds that we use to form them. High-magnification lenses are typically large due to their complex internal structure, but this lens weighs only 1.2 lb (570 g). To create the NIKKOR Z 24-200mm f/4-6.3—a powerful yet also compact high-magnification zoom, several design innovations were employed, including a new type of high-precision mold with an unconventional structure and exceptional accuracy.

This allowed Nikon’s designers to create intricately curved glass aspherical elements, capable of performing the role of multiple conventional elements in a typical lens.