NIKKOR Z Lenses: Elevating Quality for a Superior User Experience

Expert craftsmanship and advanced technology

Thanks to Nikon’s continuous improvements to quality over more than 90 years, through continuous quality improvements, NIKKOR has become a globally trusted brand.

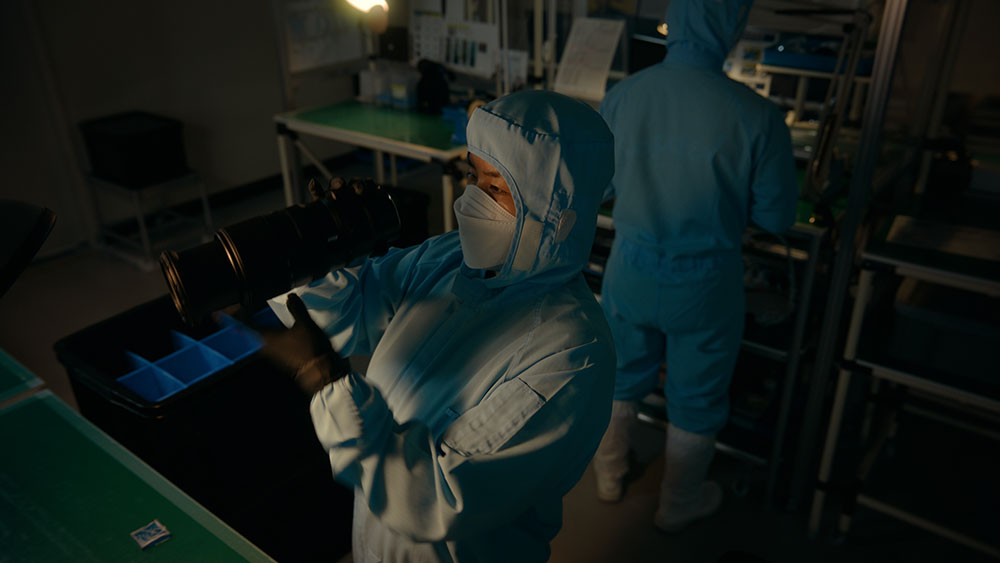

The birth of NIKKOR Z marked a new chapter in our history, driving further enhancements in the manufacturing process under even stricter standards. At every stage—from polishing to assembly and beyond—quality control specialists carry out a wide range of rigorous inspections, including detailed checks of polished lenses and operational testing after assembly.

The introduction of state-of-the-art measuring equipment refines this process even further, combining the skills of experienced professionals with advanced technology to raise quality to new levels. All of this is done to meet the diverse needs of NIKKOR Z users across every style of photography and filmmaking.

Quality assurance backed by rigorous testing, designed for real-world shooting environments

Quality assurance confirms that each finished NIKKOR lens delivers the features, performance, and reliability that its designers intended. Inspections are carried out with extreme real-world scenarios in mind, confirming that our lenses perform under conditions such as accidental drops, freezing cold or extreme heat, wind and rain, and dusty environments.

During the quality control process, specialists also evaluate the tactile feel of the exterior design and control ring of every lens, as well as the sound of the autofocus drive. It’s vital that these checks are conducted using the trained eyes, hands, and ears of experienced experts—not just machines—because the final product is designed to be used by people.

Inspection data is then shared across development, design, and manufacturing teams, providing valuable feedback that supports further quality improvements and future product planning.

Trusted quality, refined in the highlands of Japan

Nestled in the pristine natural environment of Japan’s Nasu Highlands, known for its clear air and water, Tochigi Nikon Corporation has been manufacturing NIKKOR lenses for more than 60 years. Over the decades, lens manufacturing techniques and expertise have been honed at the hands of highly skilled optical technicians known as "meisters."

These experts possess industry-leading knowledge and skills, and their craftsmanship is passed down to the next generation of meisters through strict skill evaluations.

Tochigi Nikon Corporation's expertise even extends to our overseas production bases. For example, our specialists regularly visit the Nikon Thailand factory to share their knowledge and expertise, and Tochigi Nikon Corporation also invites trainees from Nikon Thailand to Japan, to further foster the spirit of craftsmanship.

NIKKOR Z 100-400mm f/4.5-5.6 VR S

The first product of a new quality assurance system for NIKKOR lenses

The NIKKOR Z 100-400mm f/4.5-5.6 VR S was the first super-telephoto zoom lens in the NIKKOR Z line, and features “Inner Balance Technology” which keeps the center of gravity unchanged when the lens is zoomed in and out.

Due to their length and significant barrel movement, super-telephoto lenses are particularly prone to dust and dirt intrusion. For the first super-telephoto zoom lens in the NIKKOR Z lineup, we wanted to optimize both the manufacturing and quality assurance systems to ensure the highest performance. Accordingly, the production process for the 100-400mm was revised and refined, including the construction of a new cleanroom. These improvements led to the establishment of a new quality assurance system.